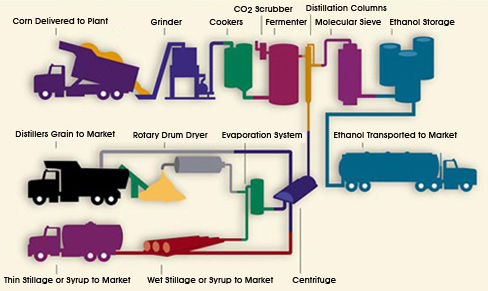

Ethanol Production Processes : ›DRY MILLING ›WET MILLING ›CELLULOSIC BIOMASS

DRY MILLING

In dry milling, the entire corn kernel or other starchy grain is first ground into flour, which is referred to in the

industry as "meal" and processed without separating out the various component parts of the grain. The meal

is slurried with water to form a "mash." Enzymes are added to the mash to convert the starch to dextrose, a

simple sugar. Ammonia is added for pH control and as a nutrient to the yeast.

The mash is processed in a high-temperature cooker to reduce bacteria levels ahead of fermentation.

The

mash is cooled and transferred to fermenters where yeast is added and the conversion of sugar to ethanol

and carbon dioxide (CO2) begins.

The fermentation process generally takes about 40 to 50 hours. During this part of the process, the mash is

agitated and kept cool to facilitate the activity of the yeast. After fermentation, the resulting "beer" is

transferred to distillation columns where the ethanol is separated from the remaining "stillage." The ethanol is

concentrated to 190 proof using conventional distillation and then is dehydrated to approximately 200 proof

in a molecular sieve system.

The anhydrous ethanol is then blended with about 5% denaturant (such as natural gasoline) to render it

undrinkable and thus not subject to beverage alcohol tax. It is then ready for shipment to gasoline terminals

or retailers.

The stillage is sent through a centrifuge that separates the coarse grain from the solubles. The solubles are

then concentrated to about 30% solids by evaporation, resulting in Condensed Distillers Solubles (CDS) or "syrup." The coarse grain and the syrup are then dried together to produce dried distillers grains with

solubles (DDGS), a high quality, nutritious livestock feed. The CO2 released during fermentation is captured

and sold for use in carbonating soft drinks and beverages and the manufacture of dry ice.*

*Information & chart cited from www.ethanolrfa.org/pages/how-ethanol-is-made |